Custom CNC Machining Service: Tailored Manufacturing to Meet Your Specifications

Custom CNC machining services offer tailored manufacturing solutions to meet the specific needs and requirements of engineering projects. Whether you’re working on a prototype, a small batch production run, or a large-scale manufacturing project, precision CNC machining services can provide you with advanced solutions to bring your vision to life.

Precision and Accuracy in Manufacturing

With custom CNC machining services, you have the flexibility to create components that match your exact specifications. From intricate design details to specific size and material requirements, CNC machining allows for a high degree of precision and accuracy in manufacturing. This means you can rely on custom CNC machining services to deliver parts that fit perfectly into your project, ensuring a seamless and efficient production process.

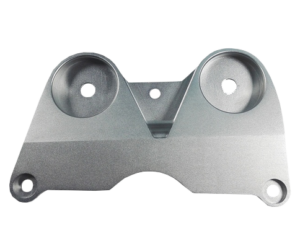

Complex Parts with Tight Tolerances

One of the key advantages of custom CNC machining services is the ability to produce complex parts with tight tolerances. CNC machines are capable of performing multiple operations in one setup, allowing for intricate shapes, angles, and contours to be created with precision and consistency. This level of accuracy is essential for ensuring the quality and functionality of your components, especially in high-tech industries such as aerospace, automotive, and medical devices.

Material Options and Versatility

Custom CNC machining services also offer a wide range of material options to choose from, including metals, plastics, and composites. Whether you need parts made from aluminum, steel, titanium, or specialty alloys, CNC machining can work with a variety of materials to meet your specific requirements. This versatility in material selection gives you the freedom to explore different options and find the best fit for your project, whether it’s for strength, durability, or cost-effectiveness.

Scalability and Flexibility

In addition to material options, custom CNC machining services can also accommodate different batch sizes, from small runs to high-volume production. This scalability allows you to adjust your manufacturing needs according to the demands of your project, without compromising on quality or efficiency. CNC machining services can handle prototypes, one-off designs, and large-scale production runs, ensuring that you have the necessary capacity to meet your engineering needs, no matter the scale.

Value-Added Services

Furthermore, custom CNC machining services can offer additional value-added services to enhance the quality and performance of your components. This may include surface finishing, heat treating, anodizing, or other post-processing treatments to improve the aesthetics, durability, or functionality of your parts. By working with a full-service CNC machining provider, you can streamline the production process and achieve a higher level of quality in your final products.

Conclusion

In conclusion, custom CNC machining services provide advanced solutions for your engineering needs by offering tailored manufacturing capabilities to meet your specifications. From intricate design details to tight tolerances, a wide range of material options, scalability in batch sizes, and value-added services, custom CNC machining can help you bring your project to fruition with precision and efficiency. Whether you’re developing a new product, replacing outdated components, or optimizing your manufacturing process, custom CNC machining services offer the expertise and technology to deliver high-quality results that meet your exact requirements.